Fan-driven air movement solutions cover a variety of uses, from cooling to air purification and more. However, not all fans are the same, and in terms of efficiency and performance, the type of bearing used has a direct impact on fan quality. To choose the right fan bearing option from the various bearing types, we will look at each in turn, and compare them to identify the best fan bearing choice you can make.

Fan Bearing Basics

Scientists have spent years analyzing bearing technology, and a complete examination of all the material available would be extremely complex and very, very long. Too long for a web article that you could read in any reasonable amount of time for sure. Instead, we’ll get to the core of the subject, and identify the differences in fans in four areas:

Type of Bearing – The common bearing choices, sleeve or ball bearing offer different properties, while sleeve bearings also have three distinct types, sleeve, hydraulic, and fluid dynamic bearings.

Noise Levels – In many applications, the levels of noise produced by the fan is crucial. It is important to remember that initial noise levels are the best-case scenario for fans, wear through use often increases noise levels over time.

Longevity – How long will the bearing last? This is a factor not only in the type of application a fan is suited for, but for replacement cycle length so that ongoing costs can be calculated.

Practicality – Some fan solutions will perform, and last, better and longer when mounted in a specific orientation. Others are unaffected by the practicalities of a specific application.

The bearing can generally be divided into 2 types: sleeve bearing and ball bearing

| Bearing Type | Structure | Fan Design | Fan Noise | Life | Cost | Fan Mounting | Operation environment | Applications |

| Sleeve Bearing | Use Grease or oil-based substance for lubrication | Simple but easy gets uneven as lubricant evaporates | Quieter at low speed, gets louder with age | 30,000 hours @ 45℃operation environment | Low, not worth maintaining, better dispose of when they go bad | Only horizontally installed, to minimize frictions | Only in normal temperatures -10℃~+55℃. | Small toys and gadgets, computer and office equipment, HVAC appliances, and industrial cabinets |

| Ball Bearing | 2-piece ball bearing for lubrication | Complex but more reliable | 1 to 3 dBA Louder at low speed, quieter at high speed and smooth | >50,000 hours@ 60℃ environment | High, but worth it for higher performance and longer life | Any directions | Can be used in harsh environments like temperature -20℃~+70℃ | high-density computer applications and data centers, electronics cooling, industrial cooling, etc. |

Sleeve Bearings

The basic sleeve bearing is a simple design and is often used in children’s toys as they are extremely cheap to manufacture. They use grease or oil-based lubrication to minimize friction, and are mostly disposable, once they wear out, they must be replaced.

| Sleeve Bearing Type | Working Principle | Noise | Disadvantages | Life | Cost |

| Sleeve Bearing | Grease or oil-based substance | Quiet in the beginning, get louder with age | Dust easily gets in, grease gets fan speed gets slower with age | 30,000 hours @ 60℃operation environment | Low |

| Hydraulic Bearing | Oil-based | Silent | Not able to repair or maintenance | 40,000 hours@ 60℃operation environment | Medium |

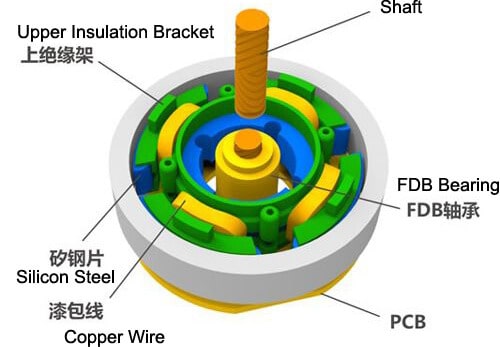

| FDB Bearing(or fluid dynamic bearing) | Oil-based | Low and smooth | Limited production capacity and availability in the market | >50,000 hours@ 60℃ environment | High |

However, there are 3 kinds of sleeve bearing:

- FDB bearing or fluid dynamic bearing: just the as fluid bearing in the article, the disadvantage of it is that there is limited production capability or capacity, which leads to limited availability in the market, only some top brands are using this type of bearing for their fans.

- Hydraulic bearing: although hydraulic bearings use the same principles as a basic sleeve bearing, they use an annular oil supply circuit for vastly improved performance, lowering noise while extending lifespan considerably.

- Sleeve bearing: lubricated by oil-based grease, most commonly used for low-value fans

| Sleeve bearing | Hydraulic Bearing | FDB bearing |

|  |  |

Ball Bearings

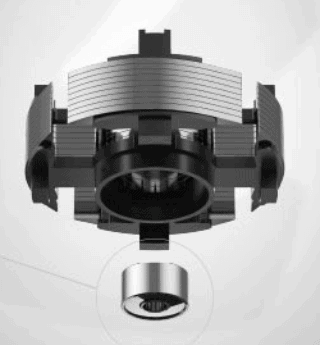

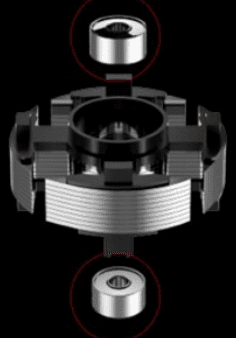

Ball bearings use a series of balls to provide low-resistance movement. They can be replaced relatively easily for maintenance, and they are long-lasting. With consistent performance and flexibility of installation, they are an excellent option for most applications.

| Ball Bearing Type | Reference Picture | Noise | Life | Cost | Disadvantages |

| Single bearing |  | Low and smooth | >40,000 hours@ 60℃ environment | Medium | Low in lifetime, louder, rarely used at the moment |

| 2-piece bearing |  | Low and smooth | >50,000 hours@ 60℃ environment | High | Popular with a wide range of choice |

Which bearing type shall I choose, the sleeve bearing fan or ball bearing fan?

The ball bearing fans are of longer life and better performance than the cooling fans of sleeve bearing and hydraulic bearing, however, sleeve bearing fans are of lower noise than ball bearing fans in the early stage of operation. The sleeve bearing types are of much lower cost than ball bearing types. First of all, the bearing type selection is normally up to the final product you are building, if it is a low-value product that is made to be used for a very short period of time, then the sleeve bearing fan is a good choice. But if you are building a product that is meant to last and perform consistently, then the ball-bearing type is always a perfect choice.